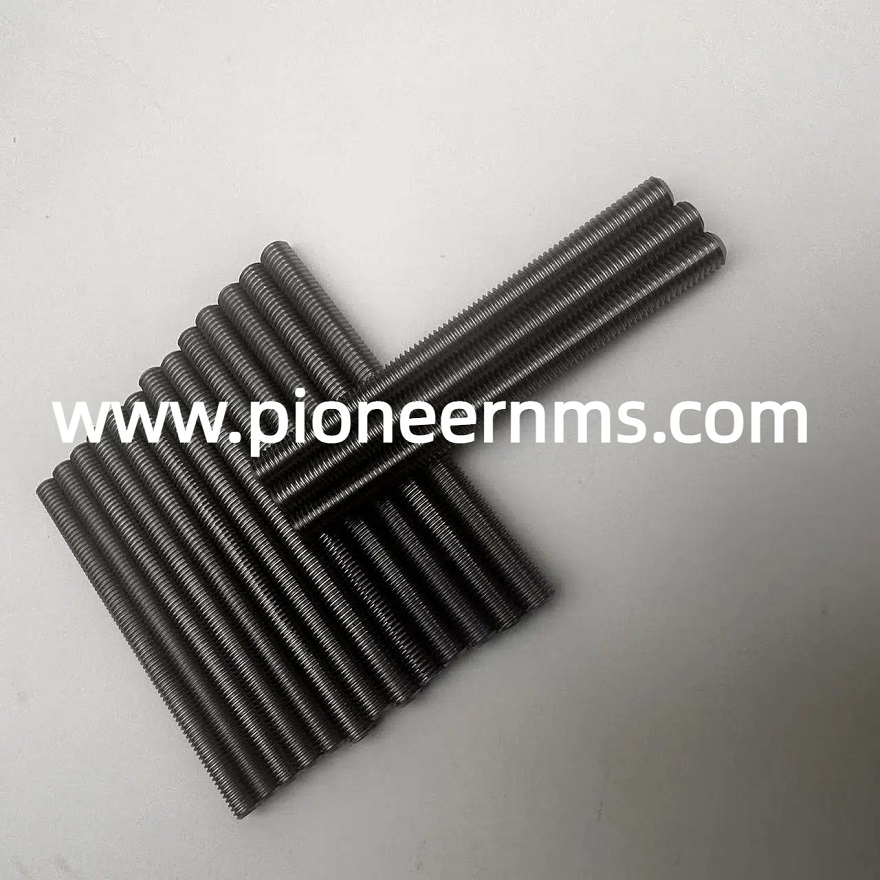

Molybdenum all-threaded bars have emerged as a critical component in vacuum heating furnace zones due to their exceptional high-temperature stability (withstanding up to 1,800°C), minimal outgassing (critical for maintaining ultra-high vacuum integrity), and superior mechanical strength in thermal cycling environments. These precision-engineered fasteners, typically made from 99.95% pure molybdenum, are specifically designed to secure heating elements and insulation systems in semiconductor, solar, and advanced materials processing furnaces, where their near-zero thermal expansion prevents loosening under extreme temperature fluctuations. Unlike conventional nickel-based alloys that degrade rapidly, molybdenum threaded bars maintain structural integrity through 500+ thermal cycles, significantly reducing furnace downtime - a key reason why leading equipment manufacturers now standardize on these components for wafer annealing, diffusion processes, and research reactor applications, with documented cases showing 30% longer service life and 40% lower contamination risk compared to alternative materials.

Post time:Sep-25-2020