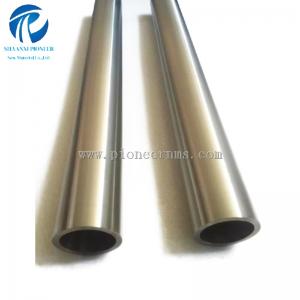

Tungsten Sputtering Target for Semiconductor & Solar Cell Coating

Tungsten Sputtering Target for Semiconductor & Solar Cell Coating

Key Features:

✔ExceptioDensity nal- 19.3 g/cm³ for superior radiation shielding

✔Extreme Heat Resistance- Withstands 3400°C melting point

✔Precision Tolerances- ±0.05mm (Standard), ±0.02mm (Precision Grade)

✔Surface Options- Mirror polish (Ra<0.4μm) or ground finish

Grade:

|

GB grade |

W |

Mo |

Ni |

|

W1 |

99.95% |

0.01 |

0.003 |

|

WAL1、WAL2 |

99.95% |

0.01 |

0.005 |

|

REMARKS: IMPURITIES ACCORDING TO GB/T 3875-2006 |

|||

Specification:

|

L (Tolerance) |

W(Tolerance) |

T(Tolerance) |

surface |

|

500~600mm |

10~500mm |

0.05~50mm |

Raw, Turned, polished |

|

Thinckness |

Tolerance |

Width |

Tolerance |

Length |

Tolerance |

Condition |

|

<0.2 |

±0.02 |

10~150 |

±2 |

500 |

±2 |

Cold rolling |

|

0.3 |

±0.03 |

10~250 |

±2 |

500 |

±2 |

|

|

0.4 |

±0.04 |

10~250 |

±2 |

500 |

±2 |

|

|

0.5 |

±0.05 |

10~300 |

±2 |

500 |

±2 |

|

|

0.8 |

±0.07 |

10~300 |

±0.5 |

500 |

±0.5 |

|

|

1.0 |

±0.08 |

10~300 |

±0.5 |

600 |

±0.5 |

|

|

1.5 |

±0.12 |

10~400 |

±0.5 |

600 |

±0.5 |

|

|

2.0 |

±0.12 |

10~500 |

±0.5 |

700 |

±0.5 |

|

|

3.0 |

±0.20 |

10~500 |

±0.5 |

600 |

±0.5 |

hot rolling |

|

4.0 |

±0.30 |

10~500 |

±0.5 |

600 |

±0.5 |

|

|

≥5.0 |

±0.40% |

10~550 |

±0.5 |

600 |

±0.5 |

Applications Section:

Ideal for Demanding Industries:

1. Medical - Radiation shielding for CT/X-ray equipment

2. Semiconductor - High-purity sputtering targets

3. Aerospace - Rocket nozzle heat shields

4. Energy - Fusion reactor first wall materials