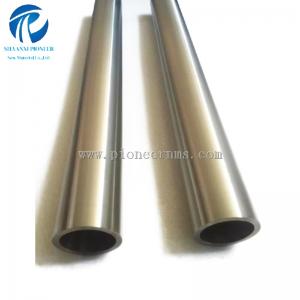

High-Temperature Molybdenum Screw

High-Strength Molybdenum Screws - The Ideal Fastening Solution for Extreme High-Temperature Environments

Professional-grade molybdenum screws, precision-machined from high-purity molybdenum material, are specifically designed to provide reliable fastening in extreme high-temperature, vacuum, and corrosive environments. With excellent thermal stability and mechanical strength, they are the ideal choice for high-temperature industrial equipment, vacuum systems, and aerospace applications.

Key Specifications

|

Parameter |

Specification |

|

Material |

Pure Molybdenum (Mo ≥99.95%) / Molybdenum Alloys (MHC, TZM) |

|

Working Temperature |

-200°C to 1900°C (in vacuum or protective atmosphere) |

|

Tensile Strength |

≥ 800 MPa (room temperature) / ≥ 200 MPa (1500°C) |

|

Surface Treatment |

Mechanical Polishing, Electro-polishing, Alkali Cleaning |

|

Thread Specifications |

Metric, UNC/UNF, Whitworth, Customization Available |

|

Head Types |

Hex Socket, Phillips, Flat Head, Round Head, etc. |

Main Application Areas

Vacuum & High-Temperature Furnaces

-

Fasteners for vacuum furnace internal structures

-

Heating element support and connection screws

-

Sintering boat and fixture assembly screws

Semiconductor & Electronics Manufacturing

-

Thin film deposition equipment internal screws

-

Plasma etching equipment fasteners

-

Ultra-high vacuum (UHV) chamber structural screws

Aerospace & Defense Industry

-

Rocket engine high-temperature component screws

-

Satellite propulsion system fasteners

-

High-temperature testing equipment special screws

Ordering Options

-

Standard sizes: 2-3 week lead time

-

Custom specifications: 4-5 week production

-

Global shipping with export compliance documentation

Request Samples or Technical Data Sheets