Why Molybdenum Substrate Matters

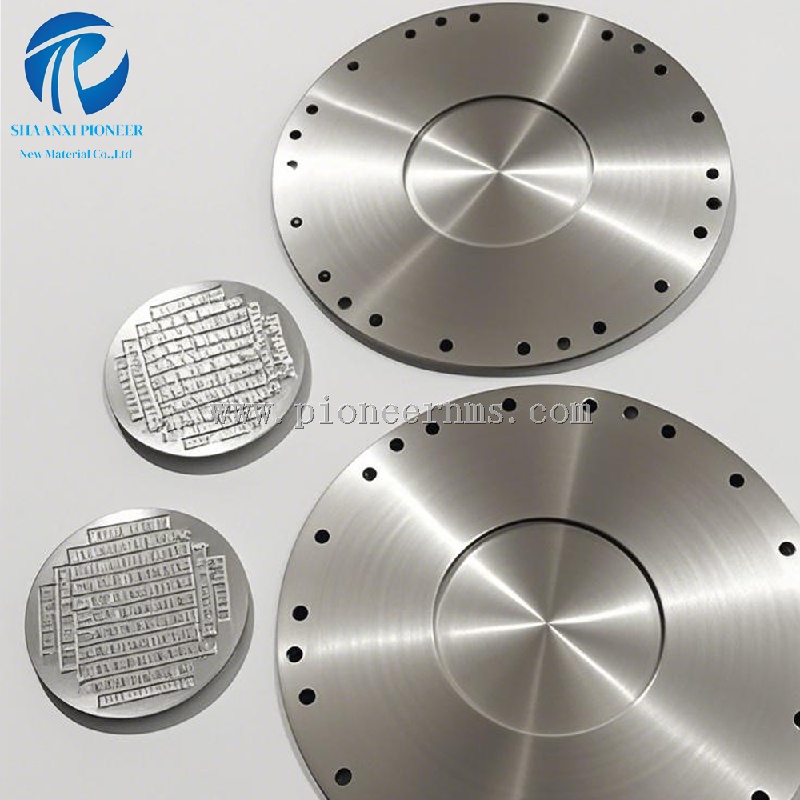

At the heart of power semiconductors such as IGBTs and SiC modules, molybdenum serves a dual role:

Thermal Buffer Zone – It acts as a CTE (Coefficient of Thermal Expansion) “translator” between silicon chips and copper heat sinks, preventing cracks and delamination under thermal cycling.

Heat Dissipation Champion – With high thermal conductivity and a melting point above 2600°C, molybdenum ensures efficient heat transfer even under extreme operating conditions.

This is not just an incremental improvement—it’s a foundational upgrade. In automotive applications, where temperature swings and power density are pushing limits, molybdenum-enabled modules are helping achieve longer lifespan, higher efficiency, and superior reliability.

The Science Behind the Performance

Molybdenum substrates excel where other materials fail. By matching the thermal expansion behavior of semiconductor materials like silicon and gallium nitride (GaN), they minimize thermomechanical stress. At the same time, their high thermal conductivity directs heat away from sensitive components, maintaining stable performance in compact, high-power designs.

Industry Impact & Future Outlook

With the global shift toward electrification, the demand for robust thermal management solutions has never been greater. Molybdenum substrates are already being adopted in advanced packaging architectures, including emerging technologies like Active Metal Brazing (AMB) ceramic substrates, which further enhance power cycling capability and bond strength.

Leading manufacturers and material suppliers—from the United States to Asia—are investing in Mo-based solutions to support the electric transition. As one industry expert noted, “You can’t talk about high-power electronics without talking about thermal management. Molybdenum makes the impossible possible.”

Post time:Sep-25-2020