How Precision-Punched Molybdenum Plates Enable Advanced Industrial Processes

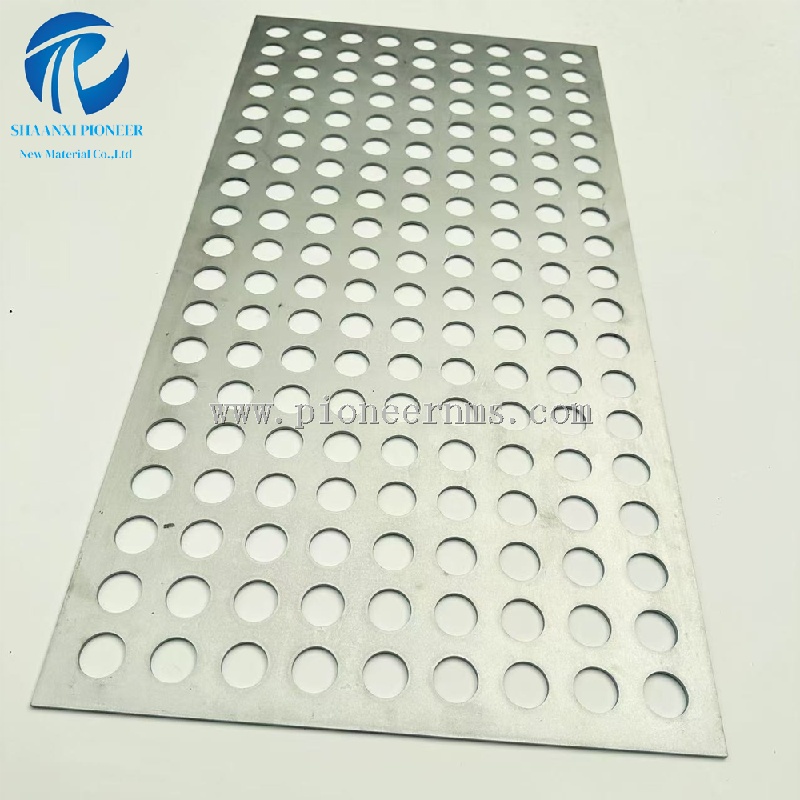

In extreme environment industries where temperature resistance and structural integrity are paramount, perforated molybdenum plates have become indispensable components. These specialized metal plates combine molybdenum's exceptional high-temperature properties with precision-engineered hole patterns to solve unique challenges across multiple high-tech sectors.

Key Advantages of Perforated Molybdenum Plates

-

Ultra-High Temperature Stability

-

Maintain structural integrity at temperatures up to 2,000°C

-

Minimal thermal expansion ensures dimensional stability in thermal cycling

-

-

Superior Gas/Liquid Flow Control

-

Precision hole patterns enable controlled distribution in furnace atmospheres

-

Optimized porosity for uniform heat and gas diffusion

-

-

Enhanced Thermal Efficiency

-

Perforations improve heat radiation and convection

-

Reduced weight while maintaining strength

-

-

Corrosion Resistance

-

Withstands aggressive chemical environments in semiconductor processing

-

Resistant to molten metal splashes in metallurgical applications

-

Critical Industrial Applications

-

Semiconductor Manufacturing:

Used as diffusion plates in crystal growth furnaces for uniform heat distribution -

Aerospace & Defense:

High-temperature filters for rocket engine components -

Glass Production:

Molten glass filtration and electrode support plates -

Nuclear Technology:

Neutron moderation and shielding components -

Thin-Film Deposition:

Sputtering targets with precision hole patterns

Custom Engineering Capabilities

Modern perforated molybdenum plates can be customized with:

-

Various hole patterns (round, square, slot)

-

Different porosity levels (5%-60%)

-

Multiple thickness options (0.5mm-20mm)

-

Surface treatments (polishing, coatings)

Post time:Sep-25-2020