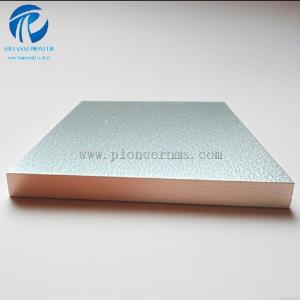

99.95% Ta High-Purity Tantalum Plate

99.95% Ta High-Purity Tantalum Plate

Premium 99.95% pure tantalum plates with exceptional corrosion resistance and high-temperature stability, ideal for chemical processing, semiconductor, and medical applications.

Key Features & Benefits

✔ Unmatched Corrosion Resistance – Resists HCl, H₂SO₄, HNO₃ (except HF)

✔ High-Temperature Performance – Stable up to 2400°C in inert/vacuum environments

✔ Biocompatibility – ASTM F560 certified for surgical implants & medical devices

✔ Precision Machining – Laser cutting, CNC milling, and drilling available

✔ Customizable – Tailored dimensions, alloys (Ta-2.5W, Ta-10W), and surface finishes

|

Parameter |

Specification |

|

Material Grade |

99.95% Ta (Ta-1), Ta-2.5W, Ta-10W (optional) |

|

Density |

16.6 g/cm³ |

|

Melting Point |

3017°C |

|

Thickness |

0.5mm – 50mm (±0.02mm tolerance) |

Primary Applications

-

Chemical Processing – Reactor linings, heat exchangers, acid-resistant vessels

-

Semiconductor – Sputtering targets, chamber components, PVD coatings

-

Medical – Bone implants, surgical tools, radiopaque markers

-

Aerospace & Nuclear – Heat shields, rocket nozzles, nuclear fuel cladding

-

Electronics – Capacitor-grade tantalum sheets

Ordering & Lead Time

-

Standard Sizes: 2-3 weeks

-

Custom Orders: 4-5 weeks (subject to specifications)

Request a Quote or Free Sample Today!