Semiconductor-Grade Molybdenum Substrate

Semiconductor-Grade Molybdenum Substrate

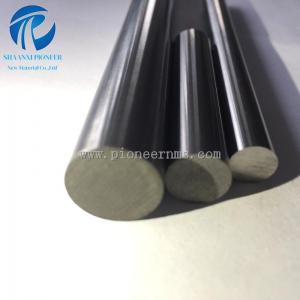

Premium-grade molybdenum substrates engineered for demanding high-temperature and semiconductor applications. Our 99.95% pure Mo substrates deliver exceptional thermal management and dimensional stability.

Key Specifications

|

Parameter |

Specification |

|

Material |

99.95% Pure Mo (TZM Alloy Optional) |

|

Purity |

≤50ppm metallic impurities |

|

Thickness |

0.1-10mm (±0.01mm tolerance) |

|

Dimensions |

Standard: 100×100mm to 500×500mm |

|

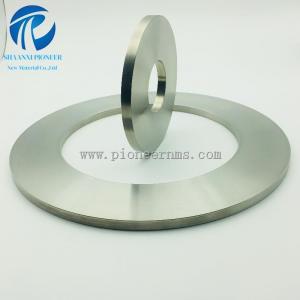

Surface Finish |

Polished (Ra ≤0.8μm), Mirror (Ra ≤0.4μm) |

|

Flatness |

≤0.1mm/100mm |

Core Advantages

✔ Thermal Stability - Withstands temperatures up to 1900°C (inert/vacuum)

✔ CTE Matching - Compatible with GaN, SiC, and other wide-bandgap semiconductors

✔ Superior Flatness - Minimizes thin film deposition defects

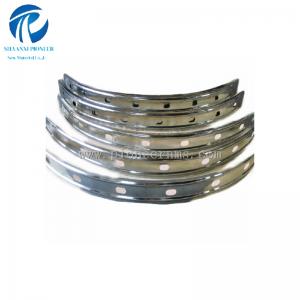

✔ Custom Processing - Laser cutting, drilling, and edge finishing available

Primary Applications

-

Power Electronics: Baseplates for SiC/GaN devices

-

LED Manufacturing: Heat spreader substrates

-

Vacuum Technology: High-temperature furnace components

-

Thin Film Deposition: PVD/CVD carrier wafers

-

X-ray Equipment: Windows and collimators

Ordering Options

-

Standard sizes: 2-3 week lead time

-

Custom specifications: 4-5 week production

-

Global shipping with export compliance documentation

Request Samples or Technical Data Sheets