Molybdenum vacuum heating furnace zone

Molybdenum Vacuum Heating Furnace Zone Solutions

Core Advantages

✅ Extreme Temperature Resistance - Manufactured from high-purity molybdenum/TZM alloys, withstanding continuous operation at 1800°C (peak 2200°C)

✅ Uniform Thermal Field - Multi-layer molybdenum heat shields ensure ±3°C temperature uniformity

✅ Extended Lifespan - Special surface treatment extends service life 3-5x vs conventional materials

✅ Ultra-High Vacuum Compatibility - Low outgassing rate (<5×10⁻⁶ Torr·L/s), suitable for 10⁻⁶ Pa UHV systems

Material Options

▸ Pure Molybdenum Zones (Mo≥99.95%)

-

Cost-effective solution for <1600°C applications

-

Typical uses: Vacuum annealing furnaces, brazing furnaces

▸ TZM Alloy Zones (Mo-0.5Ti-0.1Zr)

-

40% higher strength at 1800°C with creep resistance

-

Typical uses: High-temp sintering furnaces, crystal growth furnaces

▸ Molybdenum Disilicide Zones (MoSi₂)

-

Superior oxidation resistance for short-term air exposure

-

Typical uses: Oxidative atmosphere heat treatment

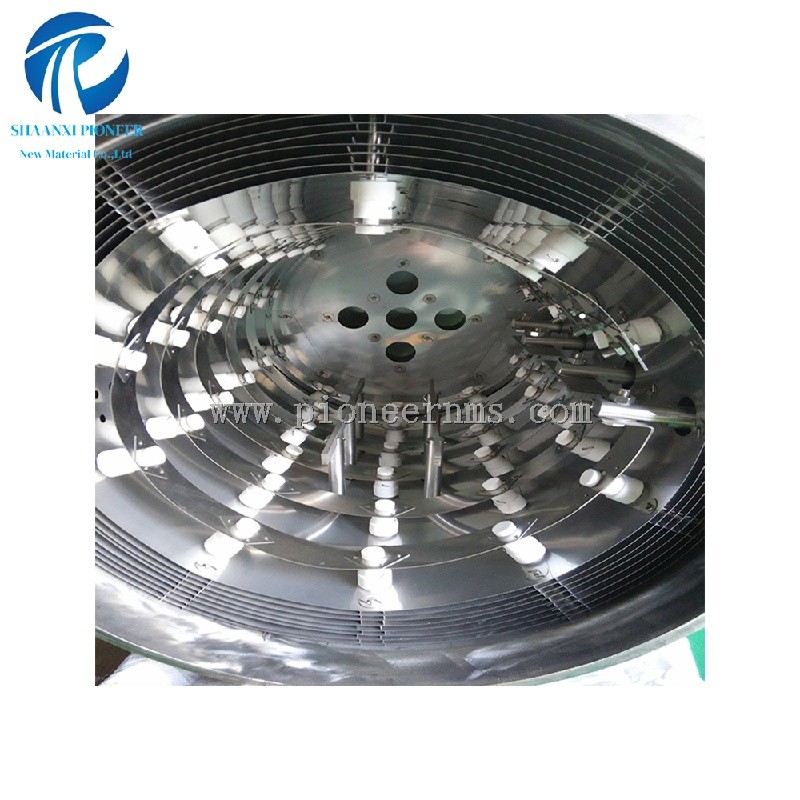

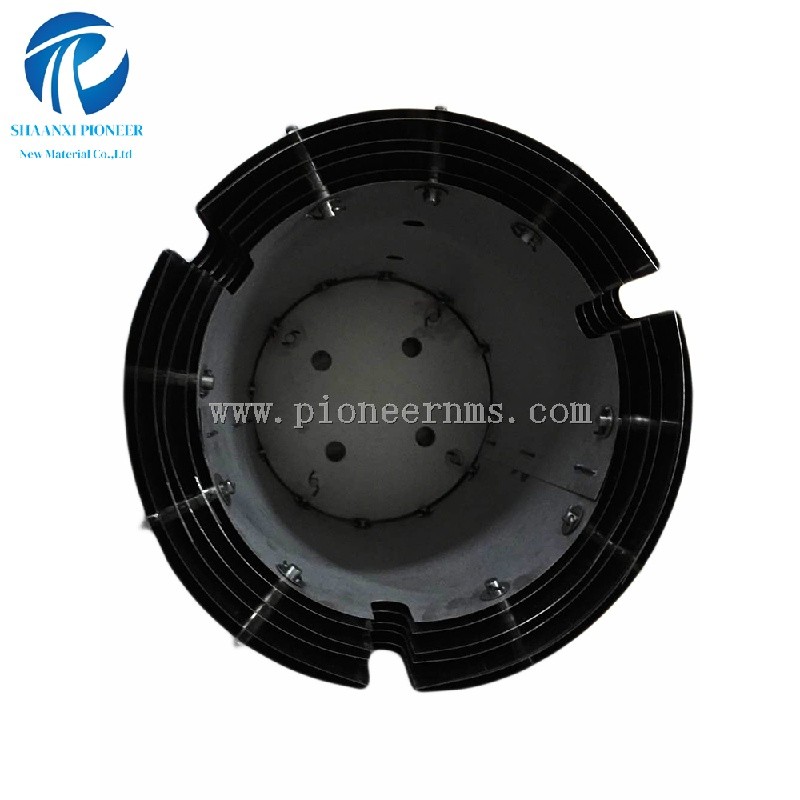

Standard Configuration

-

Heating System

-

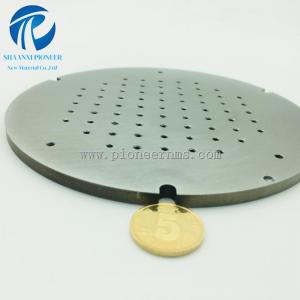

Customizable molybdenum wire/plate heaters (adjustable power density)

-

HIP-formed molybdenum electrodes

-

-

Insulation System

-

6-10 layer molybdenum radiation shields

-

Optional graphite/ceramic composite insulation

-

-

Support Structure

-

High-strength molybdenum alloy brackets

-

Water-cooled feedthrough assemblies

-

Technical Specifications

▪ Temperature Range: 800-2200°C (customizable)

▪ Vacuum Level: 10⁻³ to 10⁻⁶ Pa

▪ Heating Rate: Up to 30°C/min (programmable)

▪ Hot Zone Dimensions: Φ150-1200mm (standard)

Industry Applications

◈ Semiconductor: SiC crystal growth, wafer annealing

◈ Aerospace: CMC component sintering

◈ Advanced Materials: High-purity powder metallurgy

◈ Research: Nuclear material testing, space simulation

Custom Solutions Available - From lab-scale to industrial production systems