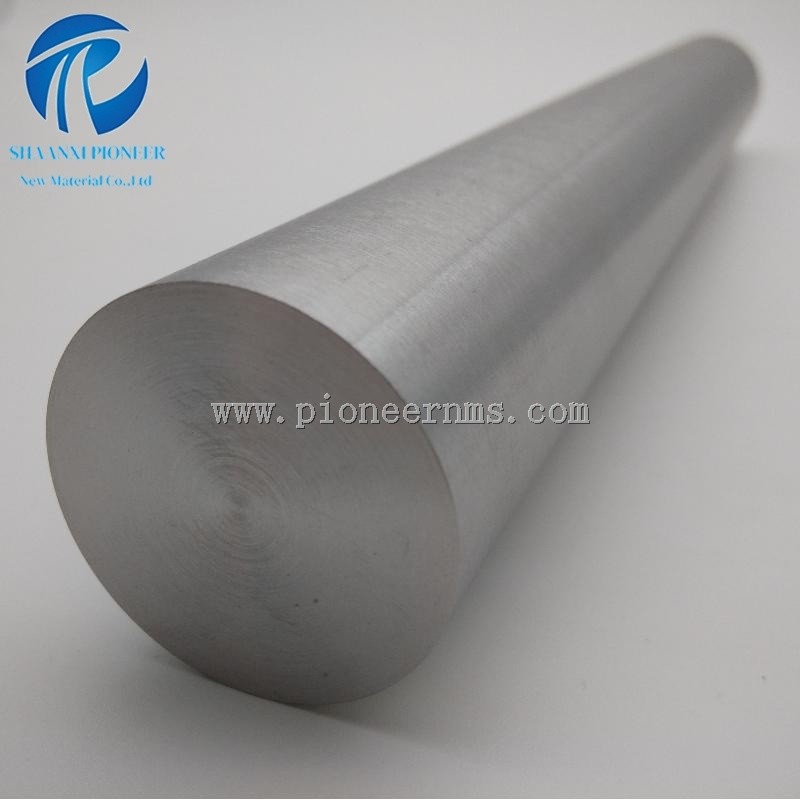

Tantalum Rod For Chemical Reactors & Medical Implants

Tantalum Rod For Chemical Reactors & Medical Implants

Premium-grade tantalum rods designed for demanding industrial and medical applications. Our 99.95% pure tantalum rods offer exceptional corrosion resistance and high-temperature performance, making them ideal for chemical processing, medical implants, and aerospace components.

Key Features & Benefits

✔ Superior Corrosion Resistance - Withstands HCl, H₂SO₄, HNO₃ (except HF)

✔ High-Temperature Stability - Operating range up to 2400°C (inert/vacuum)

✔ Biocompatible - ASTM F560 certified for surgical implants

✔ Precision Machining - Excellent for turning, milling, and threading

✔ Custom Options - Various alloys (Ta-2.5W, Ta-10W) and surface finishes

|

Parameter |

Specification |

|

Material |

99.95% Pure Ta (Ta-2.5W/Ta-10W Alloy Options) |

|

Diameter |

Ø3mm - Ø100mm (±0.02mm Tolerance) |

|

Length |

50mm - 2000mm (Custom Lengths Available) |

|

Density |

16.6 g/cm³ |

|

Melting Point |

3017°C |

Tantalum Grade

|

Grade |

ASTM |

Ta(%) |

W(%) |

Nb(%) |

|

Ta1 |

R05200, R05400 |

99.95 |

/ |

/ |

|

TaW2.5 |

R05252 |

Bal. |

2.0~3.5 |

/ |

|

TaW10 |

R05255 |

Bal. |

9.0~11.0 |

/ |

|

TaW12 |

/ |

Bal. |

11.0~13.0 |

/ |

|

TaNb3 |

/ |

Bal. |

|

1.5~3.5 |

|

TaNb20 |

/ |

Bal. |

|

17.0~23.0 |

|

TaNb40 |

R05240 |

Bal. |

|

35.0~42.0 |

Primary Applications

-

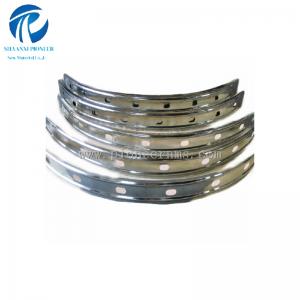

Chemical Processing: Reactor stirrers, pump shafts, heat exchanger tubes

-

Medical: Bone screws, surgical instruments, radiopaque markers

-

Aerospace/Nuclear: Rocket components, nuclear fuel rod cladding

-

Semiconductor: Sputtering target feedstock, furnace components

-

Industrial: Corrosion-resistant fasteners and fittings