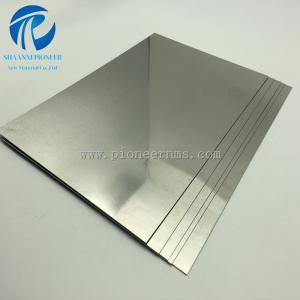

High-Temperature Molybdenum Plate - Premium Quality for Industrial & Semiconductor Applications

High-Temperature Molybdenum Plate - Premm Qiuuality for Industrial & Semiconductor Applications

Shaanxi Pioneer high-purity molybdenum plates (99.95% min) provide unmatched thermal and mechanical performance in demanding applications. Manufactured through precision rolling and annealing processes, these plates combine high melting point (2623°C/4753°F), excellent thermal conductivity, and exceptional corrosion resistance.

Core Advantages

✓ Extreme Heat Resistance - Withstands temperatures up to 2000°C in inert atmospheres

✓ Superior Thermal Conductivity - 138 W/m·K at 20°C (3× stainless steel)

✓ Low Thermal Expansion - Minimal deformation under thermal cycling

✓ Vacuum-Compatible - Low outgassing rates (<10⁻⁶ Torr)

✓ Custom Fabrication - Laser cutting, drilling, and edge profiling available

Technical Specifications

|

Grade |

Mo1, Mo2, MoLa |

|

Standard |

ASTM B387 |

|

Density |

9.8 - 10.2 g/cc |

|

Surface |

Polished,Cold-rolled, Sintered, Ground |

Applications

1. Semiconductor

• Heating elements for diffusion furnaces

• Wafer processing components

2. Aerospace & Defense

• Rocket nozzle liners

• Hypersonic vehicle thermal protection

3. Energy & Glass

• Sputtering targets for thin-film solar

• Electrodes for glass melting furnaces

4. Medical

• X-ray collimators

• Radiation shielding components