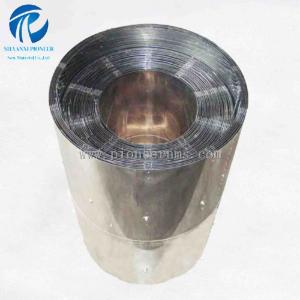

Precision Molybdenum EDM Wire

Precision Molybdenum Wire for Demanding Industrial Applications

Engineered for superior performance in EDM, high-temperature furnaces, and aerospace components. Unmatched heat resistance, strength, and consistency.

Our high-performance Molybdenum Wire is the cornerstone of modern precision manufacturing and high-temperature industrial processes. Through advanced powder metallurgy and precision drawing techniques, we deliver a product that meets the most stringent tolerances and performance criteria.

Whether you are machining complex tooling, constructing a high-temperature vacuum furnace, or developing next-generation aerospace components, our wire provides the material integrity and reliability you can depend on.

Key Advantages

High-Temperature Stability – Minimal sagging even at 1,800°C

✔ Superior Conductivity – Low resistivity (5.3 µΩ·cm at 20°C)

✔ Corrosion Resistant – Performs in inert/vacuum environments

✔ Precision Manufacturing – Laser-verified diameter control

✔ Customizable – Cut-to-length, spooling, and coatings (Au, Ni)

|

Parameter |

Specification |

|

Material Grade |

99.95% Pure Mo, TZM Alloy |

|

Diameter Range |

Ø0.01mm – Ø5mm (±0.001mm tolerance) |

|

Melting Point |

2,623°C (4,753°F) |

|

Density |

10.2 g/cm³ |

|

Surface Finish |

Bright annealed, electro-polished |

Industrial Applications

✅ Semiconductor & LED

-

Heating elements for crystal growth furnaces (GaN, SiC)

-

Wire supports for FZ (float zone) silicon refining

✅ EDM & Precision Machining

-

Cutting wire for electrical discharge machining

-

Fine-diameter tooling for micro-machining

✅ Aerospace & Defense

-

High-temperature thermocouples

-

Sensor components in jet engines

✅ Medical & Scientific

-

X-ray tube filaments

-

Electron microscope components