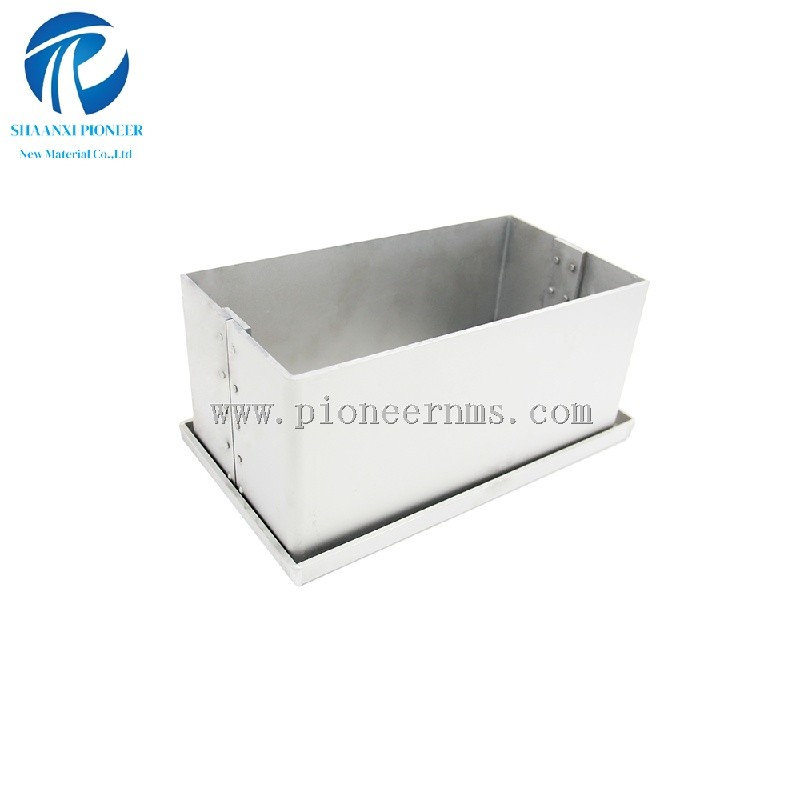

High-Purity Molybdenum Boat

High-Purity Molybdenum Boat

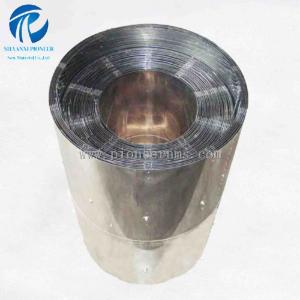

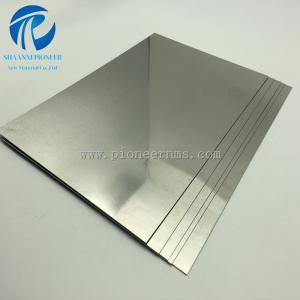

Our high-purity molybdenum boats are precision-engineered for superior performance in thermal and electron beam evaporation processes. Manufactured from 99.95% pure molybdenum with optional ceramic coatings, these boats deliver exceptional durability and consistent results in demanding thin film applications.

Key Features & Benefits

✔ Ultra-High Purity Material

-

99.95% pure molybdenum (ASTM B386 compliant)

-

Low impurity content (<50ppm) ensures contamination-free deposition

✔ Precision Manufacturing

-

Laser-cut with ±0.1mm dimensional tolerance

-

Custom geometries available (U-shaped, V-shaped, flat)

-

Smooth polished finish (Ra≤0.5μm) minimizes particle generation

✔ Advanced Coating Options

-

Al₂O₃ or Y₂O₃ CVD coatings for oxidation resistance

-

Carbon coatings available for specific applications

✔ Exceptional Thermal Performance

-

Stable operation up to 2000°C in vacuum environments

-

Uniform heat distribution for consistent evaporation rates

✔ Application-Specific Designs

-

Optimized for OLED, photovoltaic, and semiconductor processes

-

Custom configurations for research and industrial systems

Industry Applications

OLED Manufacturing

-

Uniform deposition of organic materials

-

Minimal splash for high-quality thin films

Solar Cell Production

-

Precise back electrode coating

-

Durable performance in mass production

Semiconductor Processes

-

Wafer-level metallization

-

High-purity evaporation sources

Research & Development

-

Custom alloy development

-

Specialty thin film deposition

Quality Assurance

-

Full material certification (Certificate of Analysis)

-

Dimensional inspection report with each order

Ordering Information

-

Standard Sizes: In stock for fast delivery

-

Custom Designs: Prototype to production quantities

-

MOQ: As low as 5 pieces for evaluation

-

Lead Time: 2-3 weeks for custom orders

Why Choose Our Molybdenum Boats?

-

Superior Material Quality - Highest purity molybdenum for contamination-free processes

-

Precision Engineering - Consistent performance batch after batch

-

Technical Expertise - Over 15 years of thin film solution experience

-

Custom Solutions - Tailored designs for unique applications

-

Reliable Supply - Stable inventory for production continuity

Contact our technical team today for application-specific recommendations!